Welsh Startup Space Forge was tucking in a corner of the Goodwood Festival of Speed Future Lab Building when I recently visited.

Its stand was quiet, most of the visitors collected around Amika, looking at the lifelong Humanoids presented by the British Company, Engineering Arts in partnership with the National Robotarium.

Although what the Space Forge does, underlines everything that represents Goodwood: Technology in motion and it cannot be more exciting – why here is.

The seed was in the beginning

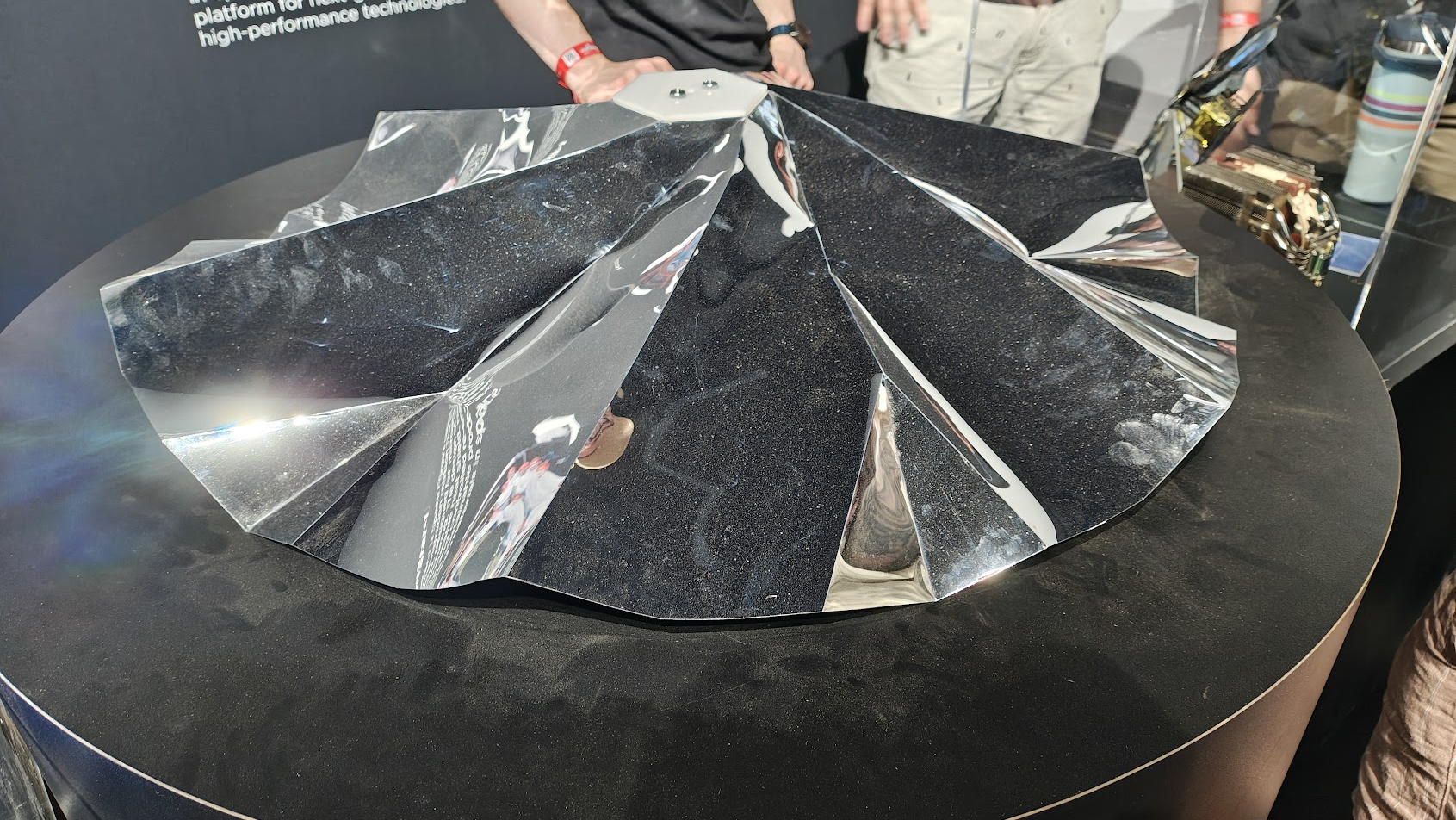

Each chip found in any electronic device – such as a robot – is likely to have a metaloid, the most common is silicon. A silicone chip would be produced from a wafer that is obtained by slicing via silicon ingot using diamond blades. That ingot, Any incenseOne is obtained from a seed.

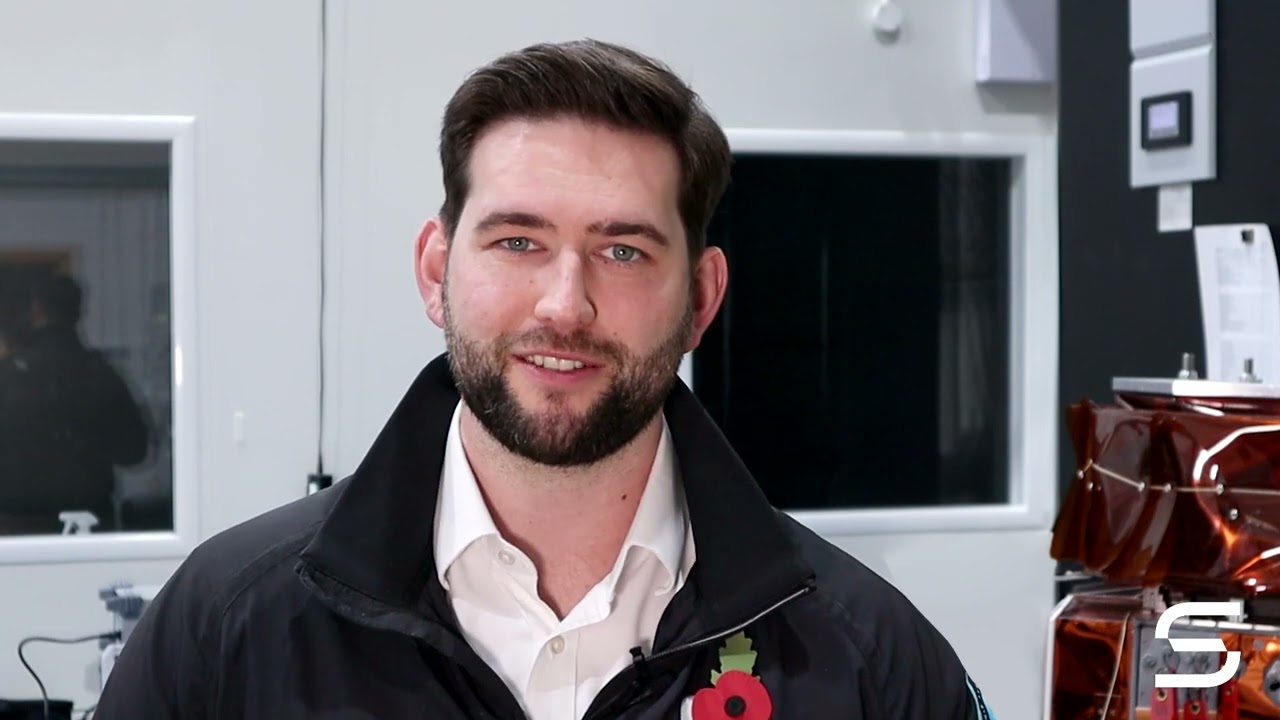

Crystal seeds, better wafers. This is why Joshua Western, CEO and Space Forge Call co-founder, ultra-high quality semiconductor substrate. This expertise, an observer told me anonymously, will draw a lot of attention from a special deep pocket line of business: Army.

In May 2025The NATO Innovation Fund was a major investor at a time consisting of the World Fund, Business Business Bank and NSSIF and injected to about 30 million dollars.

However, for now, the only public customers (and investors) Space forge admitted that Bt isSpace Forge wrote on its website, “Space-made amplifiers may exceed the total cell tower consumption”.

Extending the estimated fleet of the country of cell towers over a decade and by 2035, it is being saved about 4.3 million tonnes of CO2 – about one million ice cars equal to the CO2 emissions.

There are a lot of opportunities to produce these materials in space, but some incredible challenges (such as space radiation).

Space as a manufacturing power house

In low earth orbit, the semi-zero makes it easier to produce the seed 10x pure as compared to anything found on the Earth, which will lead to semiconductor materials from the claims of the space forge, with claims of the space forge, with the amount of defects of their worldly replants one-heaven.

It feeds a virtuous circle: low defects lead to low cost (low wastage), high efficiency, high performance for equal power consumption or similar performance with very low power consumption.

It is not only about improving existing materials. It is also about combining metals that are not possible on Earth to produce new alloys and superloys or non-metals (eg ceramic) to produce novel composes and compounds.

The trillion-dollars pharmaceutical industry is a great fit as well as a great fit with promises of better shelf life and better drug distribution methods. And let’s not start on the food industry which can also see important successes. In-spatium meat to anyone?

“We have only three rivals in the world because semiconductors are very difficult to make in space”, Western told me in the hot summer of Chichster, smiling, not because of hot weather, but because Forest 1, the company’s space manufacturing plant, was successfully launched in the late June 2025.

Future of space building

Forests are designed to be reusable and durable, but not largely scalable: the current rate of production of crystal seeds in hundreds of grams, but the scale economies will reduce the cost of operating costs, while SpaceX will help reduce competition launch costs between blue origin and other private space companies.

Joshua will not be prepared to make predictions about the future of the space forge, but gave us a clue about the direction of the journey. “We want to be a platform for others to come and work”. That platform has a name: Microgravity-e-sarvis,

This business model is as unclear as licensing of ARM: while ARM sold licenses to produce billions of chips, Space Forge will book slots for partners to produce their own mother (Kombucha), seed (plant) or starter (sour).

All others will allow constant revenue sources to increase their market share before any future new contestant by allowing others to work on their platform. “We only include four out of 100 processes that are necessary to produce a chip”, Western told me.

There is also a possibility that a foundry legend like TSMC, Samsung Foundry or Global Founders will take a fancy in this budding welsh digital dragon. Ultra pure ingots will be used as a useful USP due to high cost of production and sometimes reduced returns from shrinking lithograph.

“What is your biggest challenge right now?”, I asked Western because we ended our Emportu meeting.

“We have 40 other companies chasing this market – but my biggest challenge remains red tape”, he admitted – a common theme will be familiar with so many startups.